Manufacturer Info.

CNC machining parts have become an integral part of various industries, revolutionizing the manufacturing process and enabling the production of highly precise and customized metal products. Qingdao Merid is a company equipped with state-of-the-art machinery and a wide range of capabilities.

At Qingdao Merid, they excel in various manufacturing techniques such as stamping, bending, welding, threading, drilling, laser cutting, and CNC machining. Their expertise in CNC machining sets them apart as a leading exporter in the industry. With their advanced technology and skilled workforce, they are able to produce intricate and complex metal parts with utmost precision and efficiency. CNC machining, also known as Computer Numerical Control machining, involves the use of computerized systems to control the movement and operation of machine tools. This technology allows for the creation of highly accurate and consistent parts, ensuring a perfect fit and functionality in the final product.

The key point to highlight here is the exceptional CNC machining capabilities of Qingdao Merid. Their proficiency in this area enables them to meet the diverse needs of their clients, whether it's for automotive, aerospace, or any other industry requiring precision metal components. By choosing Qingdao Merid as your manufacturing partner, you can be assured of receiving top-quality products that meet the highest standards. With the commitment to excellence and customer satisfaction, Qingdao Merid continues to be a trusted exporter in the industry.

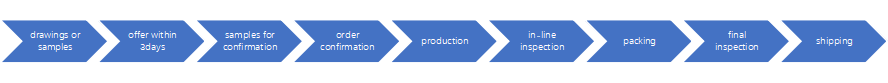

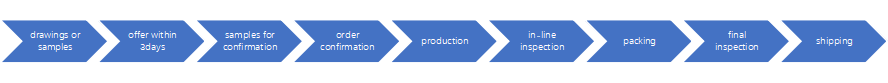

Below is the order process of customized products:

Our production capacity:

CNC turning

CNC milling

CNC drilling

CNC center

CNC machining metal parts

CNC machining plastic parts

We can make the products according to the drawings and samples.

Factory Pictures.

Production capacity

Material available | Carbon steel, Stainless steel, brass, copper alloy, aluminum alloy |

Surface treatment available | Zinc plated, Hot-dip galvanizing, Powder coating, Enameled, Anodizing, Oil spraying, Polishing, Passivate, Brush, etc. |

Metal processing available | Tooling making, Cutting, Stamping, Punching, Drilling, Welding, Bending and Tube forming, Surface finish, Assembly, Packing

CNC parts: CNC lathe milling, CNC lathe turning, CNC Center Laser cutting: 6000W laser cutting machine, work area 2000X4000mm |

Specification | OEM/ODM, based on customer' s designs, drawings or samples |

Package available | Carton, Plywood case, Pallets, Steel Cage or to order |

Documents available | CE, REACH, Rosh, UL |

Certificate | ISO9001: 2015, SGS compliance |

FAQ

Q: Is Merid a trading company or a manufacturer?

A: Merid is an original manufacturer located in Qingdao, China. Our clients include local trading companies and foreign customers. Welcome to visit our factory on site.

Q: Will the customer’s OEM products be sold to the third party?

A: We always put our customer’s benefit at first. We will never sell our customer’s products or designs to the third party without authorization. Confidentiality agreement is welcomed.

Q: How to get the price?

A: Please send your designs, drawings or samples to us. We will send our price to you based on your information.

Q: What is the MOQ ?

A: MOQ can be adjusted and discussed according to different products.

Generally, the minimum order quantity is 500pcs for each item each size.

Smaller MOQ is negotiable.

Q: What is your sample policy?

A: Free sample is available. But the freight cost should be paid by the buyer.

And the cost could be returned after the official order was placed.

Q: What is your warranty?

A: One year warranty after the shipment under correct use. To send replacement or refund in the following shipment.

Q: How about your delivery time?

A: For standard products, lead time is 15 to 30 days after received the advanced payment. For new developments, the delivery time depends on the items and the quantity of the order.

Q: What is the trade terms?

A: EXW, FOB, CFR, CIF, FCA, DDU, DDP.

Q: What is your terms of payment?

A: T/T 30% as deposit, and 70% against B/L copy or LC at sight, 100% LC,100% DP,100% OA (The price of DP and OA will expensive than the item of TT). The photos of the goods and finished packages will be sent to you before the balance payment is arranged.

Q: What is your terms of packing?

A: Generally, the goods will be packed in brown cartons, and then put into a fumigation-free wooden/plywood case or pallet if no special requirement from the buyer. The packing can also be made according to the specification of the buyer.

Qingdao Merid is a certified Chinese CNC machining parts manufacturer with ISO 9001 certification. We specialize in precision components for automotive, aerospace, and medical industries. Our 5-axis machining centers deliver complex geometries with ±0.01mm tolerances. Request a quote today!

Materials & Processing

●Materials include carbon steel, stainless steel, copper alloys, and aluminum.

●Processing covers turning, milling, drilling, and machining centers.

●Surface treatments offer zinc plating, anodizing, painting, and polishing.

●Over 10 options meet functional and aesthetic needs.

Service Scope

● CNC Machining: Handles metal and plastic parts with complex geometries.

● Prototyping & Molding: Supports 3D printing, vacuum casting, and small-batch production.

● Stamping & Welding: Uses 16-500T presses, laser cutting (2000×4000mm), and robotic welding.

● OEM/ODM: Custom designs from drawings or samples.

Capabilities

● Equipment: CNC lathes, mills, and machining centers.

● Laser Cutting: 6000W equipment covers 2000×4000mm work areas (updated in 2023).

● Bending: Maximum bending length of 3 meters.

● Welding: Robotic, laser, and TIG welding.

Design & Quality

● Software: Auto CAD, SolidWorks, and ProE enable 2D/3D design.

● Surface Finishing: Partners provide plating and spraying with strict quality checks.

● Packaging: Custom solutions include cartons, pallets, or plywood cases.

Quality Assurance

● Certifications: ISO9001:2015, IATF16949, SGS, CE, RoHS, and UL.

● Control: Full-process monitoring from raw materials to final inspection.

● Warranty: 1-year warranty with replacements or refunds.

Order & Delivery

● MOQ: Negotiable, small MOQ is acceptable

● Process: Submit drawings/samples → Quote → Prepayment → Production → Delivery.

● Payment: 30% prepayment via T/T. Balance options include T/T, LC, DP, or OA.

● Delivery: 15-30 days for standard orders. New products vary by complexity.

● Shipping: Supports EXW, FOB, CIF, and DDP terms.

Products and Services Core Products CNC Machining Parts:Qingdao Merid offers a wide range of precision CNC machining parts made from materials such as carbon steel, stainless steel, copper alloys, and aluminum alloys.

These materials are selected for their strength, durability, and versatility, ensuring that the final product performs excellently under various conditions. The machining processes employed include turning, milling, drilling, and operations using machining centers.

These versatile processes allow for the creation of highly intricate parts with precise dimensions and excellent surface finishes, meeting a broad spectrum of industrial requirements.

Surface Finishing:

The company provides an extensive variety of surface treatments to enhance the durability and appearance of parts. With over 10 different methods available, including zinc plating, anodizing, powder coating, and polishing, Qingdao Merid ensures that the parts are not only functional but also meet aesthetic standards. These surface treatments help improve the corrosion resistance, wear resistance, and overall longevity of the products, making them suitable for demanding environments across various industries.

Service Range CNC Machining:

The company specializes in both metal and plastic high-precision CNC machining, which allows for the production of complex geometries with tight tolerances. This service is ideal for industries that require precision and customization, such as automotive, aerospace, and medical equipment manufacturing.

The team at Qingdao Merid utilizes state-of-the-art machinery to ensure each component meets the highest standards of quality and precision. Rapid Prototyping and Mold Manufacturing:For industries that need fast development and testing of prototypes, Qingdao Merid offers rapid prototyping services using 3D printing and vacuum casting.

These methods are particularly beneficial for small batch production, enabling businesses to test their designs before committing to large-scale manufacturing. Mold manufacturing capabilities further enhance this process, allowing for cost-effective production of prototypes and low-volume parts.

Stamping and Welding:

With stamping equipment ranging from 16 to 500 tons, the company can handle a wide variety of stamping needs, from simple to highly complex parts. Additionally, Qingdao Merid utilizes advanced laser cutting, bending, and robotic welding technologies to deliver high-precision, durable components for different applications.

OEM/ODM Services:

Qingdao Merid offers tailored OEM and ODM services, ensuring that each product is customized according to customer designs or samples. This flexibility makes the company an ideal partner for businesses seeking unique, customized parts to fit specific needs.

Production Capacity and Technical Equipment Processing Technology:

The company employs advanced CNC equipment, including lathes, milling machines, and machining centers, to produce high-quality parts. These machines are crucial in creating components with precise dimensions and complex geometries, ensuring optimal functionality.

Laser Cutting:

Qingdao Merid recently upgraded its capabilities by adding a 6000W laser cutting system with a working area of 2000mm × 4000mm. This addition allows for the efficient and precise cutting of large sheets of metal and other materials, enabling the company to handle even the most demanding projects.

Bending Equipment:

The company’s bending equipment can handle materials up to 3 meters in length, providing excellent flexibility for producing parts of various shapes and sizes. This equipment is ideal for manufacturing parts requiring precise bends, ensuring accuracy and consistency across batches.

Welding Technologies:

Qingdao Merid employs several advanced welding techniques, including robotic welding, laser welding, and TIG welding. These methods ensure high-quality welds that are strong and durable, meeting the stringent requirements of various industries such as automotive and aerospace.

Quality Assurance System Certification and Qualifications:

The company holds numerous certifications, including ISO9001:2015, IATF16949, SGS, CE, RoHS, and UL, demonstrating its commitment to maintaining high-quality standards. These certifications validate the company's ability to consistently produce high-quality products that meet international safety and environmental standards.

Quality Control:

Qingdao Merid’s quality control system monitors the entire production process, from raw material procurement to final inspection. This comprehensive approach ensures that every product leaving the facility meets strict quality standards. Continuous improvements are made based on regular process reviews and customer feedback.

Warranty and Customer Support:

The company offers a one-year warranty on its products, providing customers with confidence in the durability and performance of the items.

Additionally, Qingdao Merid offers comprehensive after-sales support, ensuring that any issues are promptly addressed and resolved. Industry Applications Qingdao Merid’s products find applications across various industries:

●Construction: Providing metal structural parts and connectors.

●Automotive: Manufacturing precision components and prototype development.

●Medical: Supplying components for medical equipment, with an emphasis on high precision.

●Aerospace: Specializing in the production of complex geometric parts and lightweight materials.

●Consumer Electronics: Delivering both exterior casings and internal structural components.

Technical Advantages Advanced Equipment:

Qingdao Merid’s state-of-the-art equipment, including a 6000W laser cutting machine, 3-meter bending machine, and robotic welding line, ensures that the company can meet the most demanding manufacturing requirements.

Comprehensive Service:

The company provides a one-stop service that covers everything from design and stamping to surface finishing, assembly, and packaging, ensuring a streamlined process for customers.

Flexible Production:

Whether customers need small batch runs or large-scale production, Qingdao Merid can accommodate a variety of orders, making it a versatile partner for businesses of all sizes.

In summary, Qingdao Merid’s combination of advanced technology, expert craftsmanship, and dedication to quality makes it a leader in the field of CNC machining and manufacturing. Their ability to provide customized solutions tailored to the unique needs of each industry sets them apart as a reliable and trusted partner.

| Parameter | Value |

| Material Type | Stainless Steel, Aluminum Alloy, 45# Steel |

| Processing Stage | Roughing (开粗), Finishing (光刀) |

| Tool Type | Fly Cutter (飞刀), White Steel Flat End Mill (白钢平刀), Tungsten Carbide Ball Nose Cutter (钨钢球刀) |

| Recommended Tool | - Roughing: Fly Cutter for 45# Steel

- Finishing: Tungsten Carbide Ball Nose Cutter for Stainless Steel |

| Spindle Speed Range | - Roughing: ≤8000 RPM (普通机)

- Finishing: Adjusted for surface precision |

| Feed Rate | - 45# Steel Roughing: ~1200 mm/min

- Stainless Steel Finishing: Optimized for tool durability |

| Machine Compatibility | Standard CNC Machines (≤8000 RPM) |

| Surface Treatment | Zinc Plating, Anodizing, Painting, Polishing |

| Quality Certification | ISO9001:2015, IATF16949, CE, RoHS |

| Minimum Order Quantity | 1 ton (negotiable) |

Key context references:

• Tool selection depends on material hardness (e.g., tungsten carbide for stainless steel finishing).

• Feed/speed parameters vary between roughing (heavy cuts) and finishing (light cuts).

• Standard machines (<12,000 RPM) use conservative speed parameters.

Product Features

Material Compatibility

Processes carbon steel, stainless steel, copper alloys, and aluminum alloys. Supports custom material requests for specialized applications.

Precision Machining a

Performs turning, milling, drilling, and multi-axis machining. Achieves tight tolerances for complex geometric parts.

Surface Finishing

Offers 10+ treatments including zinc plating, anodizing, painting, and polishing. Ensures corrosion resistance and aesthetic requirements.

Rapid Prototyping

Combines 3D printing (SLA/SLS/MJF) and vacuum casting. Delivers functional prototypes within 1-2 weeks for design validation.

Stamping & Welding

Uses 16-500T hydraulic presses and robotic welding. Covers laser cutting (2000×4000mm workspace) and 3-meter bending capacity.

Custom Production

Accepts OEM/ODM orders from drawings or samples. Adjusts MOQ to 500 units or below for flexible small-batch needs.

Advanced Equipment

Operates CNC lathes, mills, and 5-axis machining centers. Includes 2023-upgraded 6000W laser cutting systems.

Design Support

Utilizes AutoCAD, SolidWorks, and ProE for 2D/3D development. Provides DFM feedback to optimize part manufacturability.

Quality Certifications

Complies with ISO9001:2015, IATF16949, CE, and RoHS standards. Maintains traceability from raw materials to final inspection.

Order Flexibility

Processes orders from 1 ton (negotiable MOQ). Supports EXW, FOB, CIF, and DDP shipping terms for global clients.

Payment Options

Requires 30% T/T prepayment. Accepts LC, DP, or OA for balance payments with order photo confirmation.

Delivery Timeline

Ships standard orders in 15-30 days post-prepayment. Extends timelines for new product development based on complexity.

Sample Policy

Provides free samples (customer pays shipping). Refunds sample shipping costs after bulk order confirmation.

Data Security

Signs NDAs to protect client IP. Restricts design access to authorized personnel only.

Industry Applications

Serves automotive (precision components), medical (surgical tools), and aerospace (lightweight structures).

Partner with Qingdao Merid for precision CNC machining parts that meet industrial demands.

Our ISO-certified production ensures consistent quality across carbon steel, aluminum, and specialty alloys. Enjoy flexible MOQs (negotiable from 1 ton), 15-30 day lead times, and global logistics support.

Custom solutions for automotive, aerospace, and medical sectors are backed by 24/7 technical assistance.

Contact us for bulk pricing and tailored project terms.