Product Advantages

Wide Market Reach

With strong demand across North America, Western Europe, and Northern Europe, our 1/2" Hot-Dip Galvanized Flat Washer is a trusted solution in various global markets. Its versatility makes it suitable for a wide range of industries and applications.

Diverse Client Base

This washer caters to a broad spectrum of customers, including retailers, engineers, wholesalers, brand businesses, manufacturers, and private users.

High Quality & Reliability

Our 1/2" washer is engineered to meet the demands of both professional and personal applications. Whether used in construction, manufacturing, or maintenance, it guarantees secure fastening and reduces the risk of failure.

Cost-Effective Solution

Offering a combination of quality, durability, and competitive pricing, this washer provides excellent value for both small and large-scale operations. It helps businesses reduce downtime and maintain efficiency.

1/2" Hot-Dip Galvanized Flat Washer for Secure Fastening

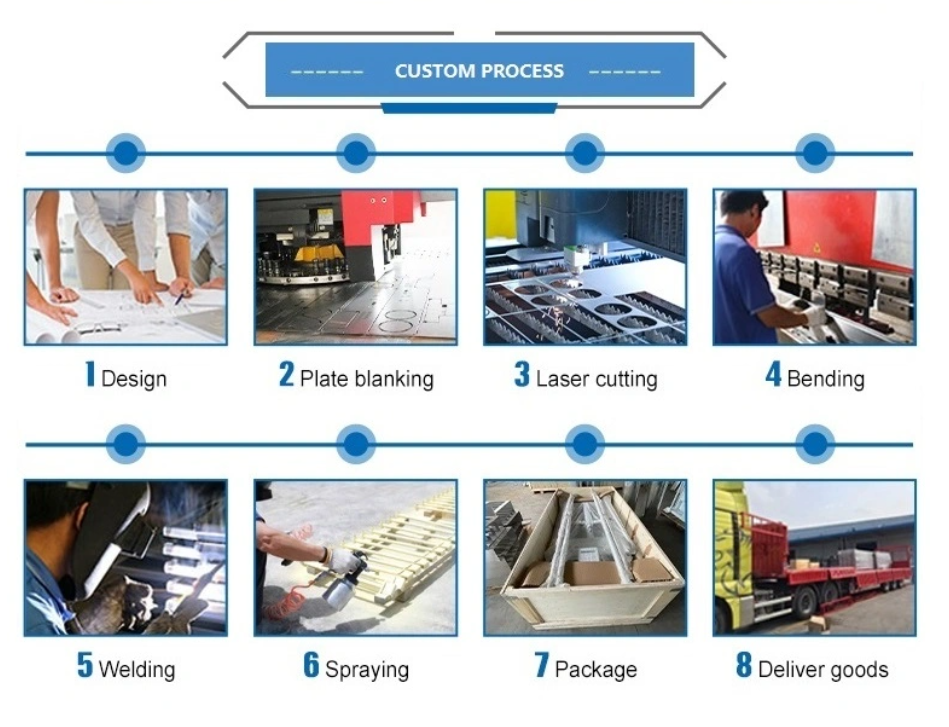

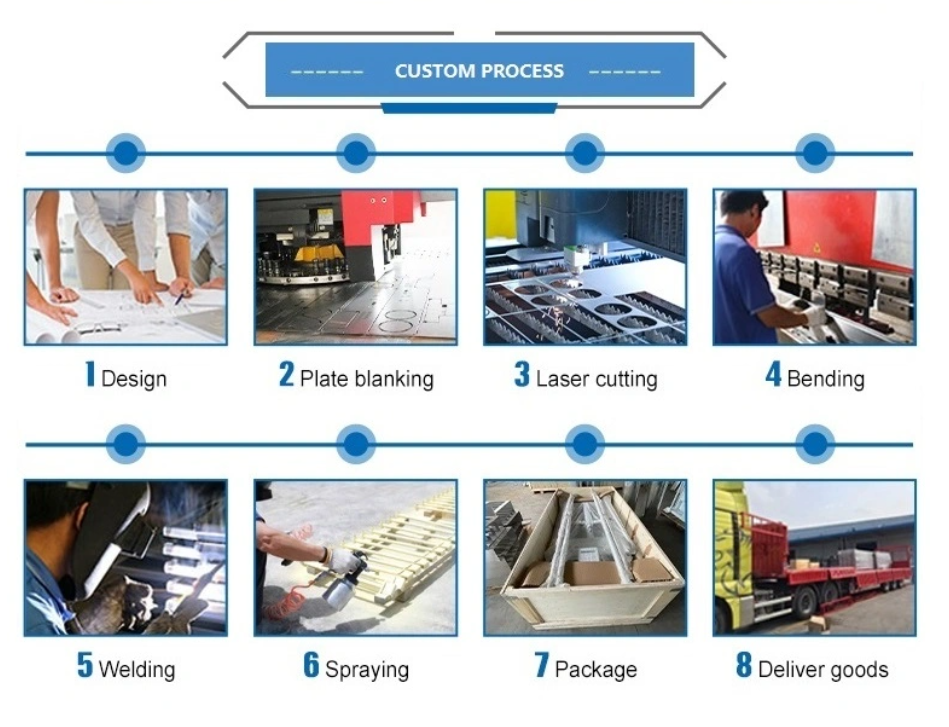

Custom Process Flow

Design

The process begins with the design phase, where our team collaborates with the customer to understand specific requirements. Custom designs are created based on dimensions, materials, and other specifications to ensure the product meets the desired standards.

Plate Blanking

In this stage, large metal plates are cut into the required shape and size based on the design specifications. Plate blanking ensures that we have the right size pieces ready for further processing.

Laser Cutting

Using advanced laser cutting technology, we achieve precise cuts on the blanked plates. This ensures high accuracy and clean edges for complex shapes and designs, meeting the tightest tolerances.

Bending

After cutting, the pieces are carefully bent using specialized equipment. This stage shapes the parts into their final form, ensuring that they fit perfectly within the larger assembly or product.

Welding

The parts are then welded together to create a strong and stable structure. Our skilled welders use advanced techniques to ensure the welds are clean, durable, and meet quality standards.

Spraying

Following welding, the products are treated with a protective coating. Spraying ensures that the products have enhanced corrosion resistance, durability, and an aesthetically pleasing finish, whether it's for functional or decorative purposes.

Packaging

Once fully assembled and coated, the products are carefully packaged to prevent damage during transit. Our packaging ensures that each item arrives at its destination in perfect condition.

Delivery

The final step involves shipping the finished products to the customer. We offer various delivery options, ensuring timely and secure transportation of goods to meet customer needs.

This custom process flow ensures that each product is made to the highest standards of quality and craftsmanship, tailored to the unique requirements of our clients.

Custom Product Process Flow

Drawings or Samples

The process begins with the customer providing either technical drawings or physical samples. These details help us understand the exact requirements, specifications, and design preferences for the custom product.

Offer Within 3 Days

Once we receive the drawings or samples, we provide a detailed quote within 3 days. This offer includes pricing, lead times, and any other pertinent details to ensure the customer has a clear understanding of the product’s cost and timeline.

Samples for Confirmation

After the customer approves the offer, we produce a prototype or sample of the custom product for confirmation. This allows the customer to evaluate the product’s design, dimensions, and functionality before proceeding with full production.

Order Confirmation

Once the customer confirms the sample, the order is officially confirmed. We finalize production timelines, materials, and quantities, ensuring everything aligns with the customer’s needs.

Production

Production begins according to the agreed-upon schedule. We begin manufacturing the custom products, adhering to high-quality standards and precise specifications to ensure consistency and accuracy.

In-Line Inspection

During production, we conduct in-line inspections at various stages to monitor quality and ensure that the products meet the required standards. This process helps identify any issues early, preventing defects and ensuring product integrity.

Packing

After production, the finished products are carefully packed to protect them from damage during transit. We use protective materials and secure packaging to ensure that each product arrives safely at its destination.

Final Inspection

Before shipping, a final inspection is conducted to ensure all products are of the highest quality. Any remaining issues are addressed, and the products are thoroughly checked for defects, measurements, and finish.

Shipping

Once the products pass final inspection, they are shipped to the customer. We offer reliable shipping options to ensure the products are delivered on time and in perfect condition.

This custom product process ensures that each step is carefully managed to meet customer requirements and provide the highest quality, on-time delivery.

Product Specifications

Material available | Carbon steel, Stainless steel, brass, copper alloy, aluminum alloy |

Surface treatment available | Zinc plated, Hot-dip galvanizing, Powder coating, Enameled, Anodizing, Oil spraying, Polishing, Passivate, Brush, etc. |

Metal processing available | Tooling making, Cutting, Stamping, Punching, Drilling, Welding, Bending and Tube forming, Surface finish, Assembly, Packing

CNC parts: CNC lathe milling, CNC lathe turning, CNC Center Laser cutting: 6000W laser cutting machine, work area 2000X4000mm |

Specification | OEM/ODM, based on customer' s designs, drawings or samples |

Package available | Carton, Plywood case, Pallets, Steel Cage or to order |

Documents available | CE, REACH, Rosh, UL |

Certificate | ISO9001: 2015, SGS compliance |